Kepma Guitars Wood Process

The key to premium performance and longevity in any guitar is maintaining a proper environment. Because the guitars primary components are made of wood, it’s important to know the conditions on how your guitar has been manufactured and the processes involved in developing the wood.

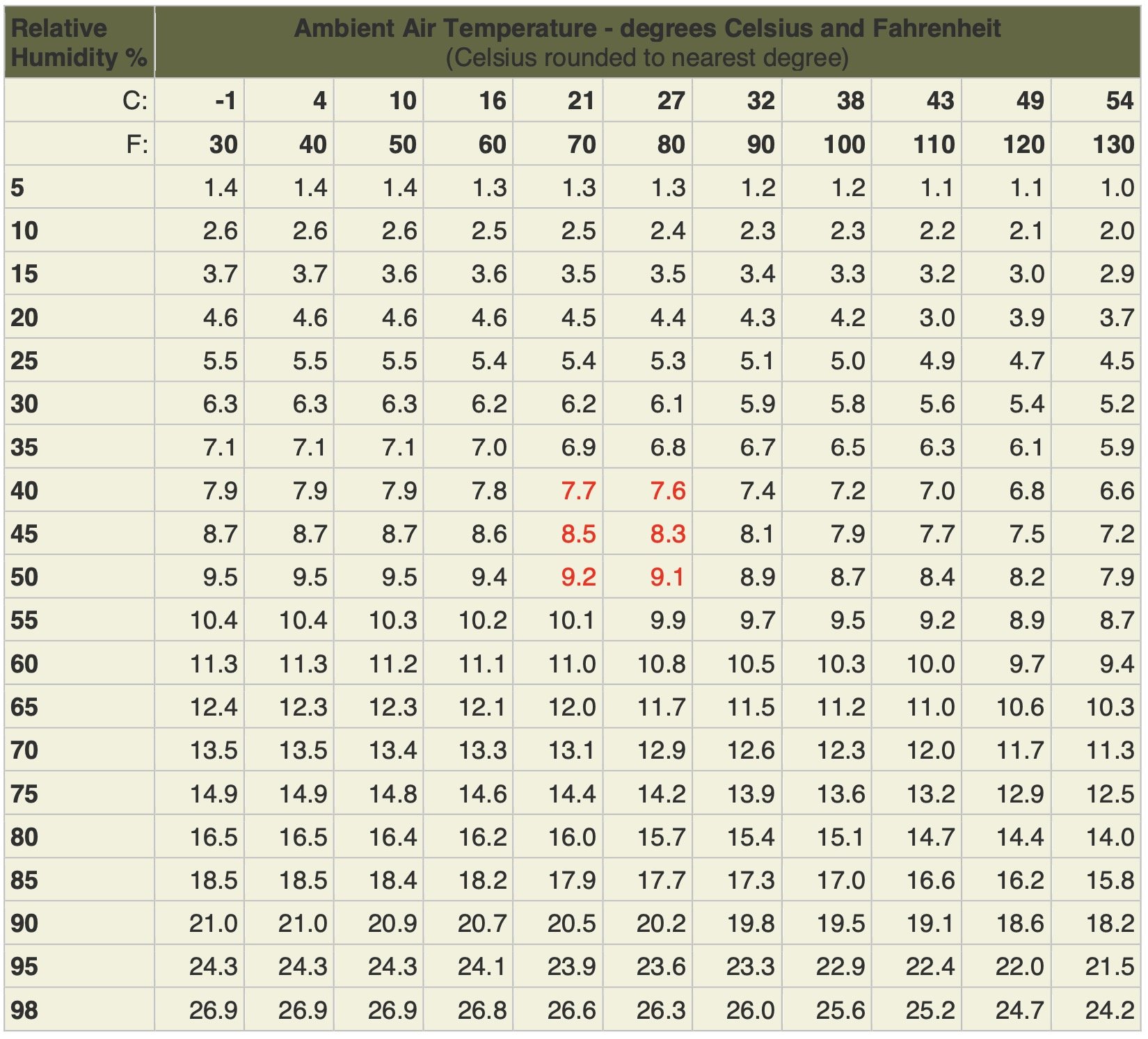

Think of wood as a dense sponge. It can absorb surrounding moisture in a humid environment or lose it in an arid setting. Wood is absorbing and losing moisture all the time, it gets its balance once the velocity of absorption equals the loss, then the relative moisture content will minimally fluctuate. This is known as Equilibrium Moisture Content or EMC. EMC depends on the relative moisture content and temperature shown in the table below.

EMC Chart

The table below provides EMC values for a representative range of atmospheric conditions that wood is likely to be exposed to. Values in this table are applicable to wood of any species for most practical purposes.

The moisture content at which wood neither gains nor loses moisture is the EMC. The equilibrium is dynamic in nature because the ambient conditions, such as relative humidity and temperature, are constantly changing.

When a guitar is placed in a controlled environment, it tries to achieve equilibrium with the environment over time. The moisture content adjusts to the relative humidity and temperature of its surroundings. After a certain period of time, the wood’s moisture content stops changing. This moisture level is termed the EMC.

As long as the relative humidity and temperature of its surroundings don’t change, the wood’s moisture level remains at its EMC once reached. That’s why acclimating wood (i.e. your guitar) to its final surroundings is vital before using it. Once it acclimates to its environment and reaches the EMC, the risk of physical changes occurring in the wood is minimal… unless the environment changes.

Therefore, knowing the typical or “relative” humidity of a guitar’s playing environment is the target of the manufacturer’s Equilibrium Moisture Content or the wood. Equilibrium Moisture Content or EMC is the percent moisture content that wood will eventually reach given the ambient conditions remain relatively constant.

Therefore, it is critical to remove the wood’s original moisture content to an acceptable level to prepare it for the production and assembly of a guitar. Starting with wood that is too wet will mean inevitably it will dry more and shrink. Wood that is too dry will want to absorb moisture in from even a comfortable climate and expand in volume.

Kepma’s wood process begins with the selection of wood suppliers with access to woods internationally. All suppliers are vetted to ensure they are recognized by the government as stewards of the materials they supply and can provide proper authentication paperwork. All tops used by Kepma are aged North American solid spruce and are quarter-sawn to ensure stability.

This wood goes through a preliminary drying process to remove the woods natural moisture before it is sent to Kepma. Depending on the wood and the purpose of the wood, this can be a process up to 12 months. But this environment is still subject to a wide range of temperature and humidity variations.

After Kepma receives the initially dried wood in either block, precut or blank form, each piece is separated to allow further air-drying. This is a type of stress relief for the wood as it loses more moisture and maintains proper shape. Kepma has wood storage facilities are specifically designed for even air flow throughout to maintain a proper drying environment.

Prior to production, the wood processes like necks, fingerboards, solid backs/sides and even bracing are slow “cooked” at a low, controlled temperature to continue reducing the remaining moisture in the wood down to a target percentage. The goal is to achieve a target EMC of around 7.5-8.5%. Kepma’s custom wood kiln is specially designed to low heat all wood materials used in the guitar and can “bake” up to 1000 necks at a time.

The next stage on select models is to add further treatment to the solid tops of the instruments. This process is a multi-faceted process rather than simply applying heat as with a kiln. Instead, this process includes applying heat along with steam humidity and pressure to cook out the cells within plants that retain moisture preventing the tops from absorbing moisture in the future. This process reduces the hydrophilic or “water-loving” group inside the wood and relax its moisture absorption ability. So, the wood gains more stability and will varies less in shape when the environment changes.

Often called torrefication, Kepma’s thermal wood processing provides tops with light weight and great strength. It also yields a warmer tone and even a slightly darker appearance than the woods natural appearance. Tops that claim to have a torrefied finish but have a dark or ashen shade indicate that they have actually burnt the cellular structure of the wood making it potentially weaker and prone to cracking.

Natural solid spruce top wood versus Kepma torrefied spruce top

Kepma features a production environment of 21 degrees Celsius/70 degrees Fahrenheit and a relative humidity of 45%-55%. The table below illustrates that the EMC will be around 8.4% (This EMC works well in the widest majority of climates in USA). So, keeping the humidity/temperature of production line provides future stability of guitars.

Below is a chart of EMC average percentages in various parts of the US at various times of year.