Kepma R&D Facility

The Kepma R&D facility is where all the magic happens. Every innovation in guitar design and construction starts right here in this room…

Tone and Bracing Woods

It takes constant commitment to the quest for great acoustic sound to produce Kepma quality… and the right combination of wood, hands and heart.

More woods...

At Kepma we experiment with multiple combinations of woods to get the right sound — balanced, rich sound with just the right amount of low end fullness, midrange punch and sparkle at the top end that cuts through the mix.

Hands. Tools.

Every detail of a Kepma Elite Series Guitar is created and fine-tuned by hand before converting over to more efficient production methods. This is what makes Kepma Elite Guitars special… and affordable.

The room where it happens...

We spend countless hours dedicated to the pursuit of handcrafting the perfect guitar. It’s just what we do… every time.

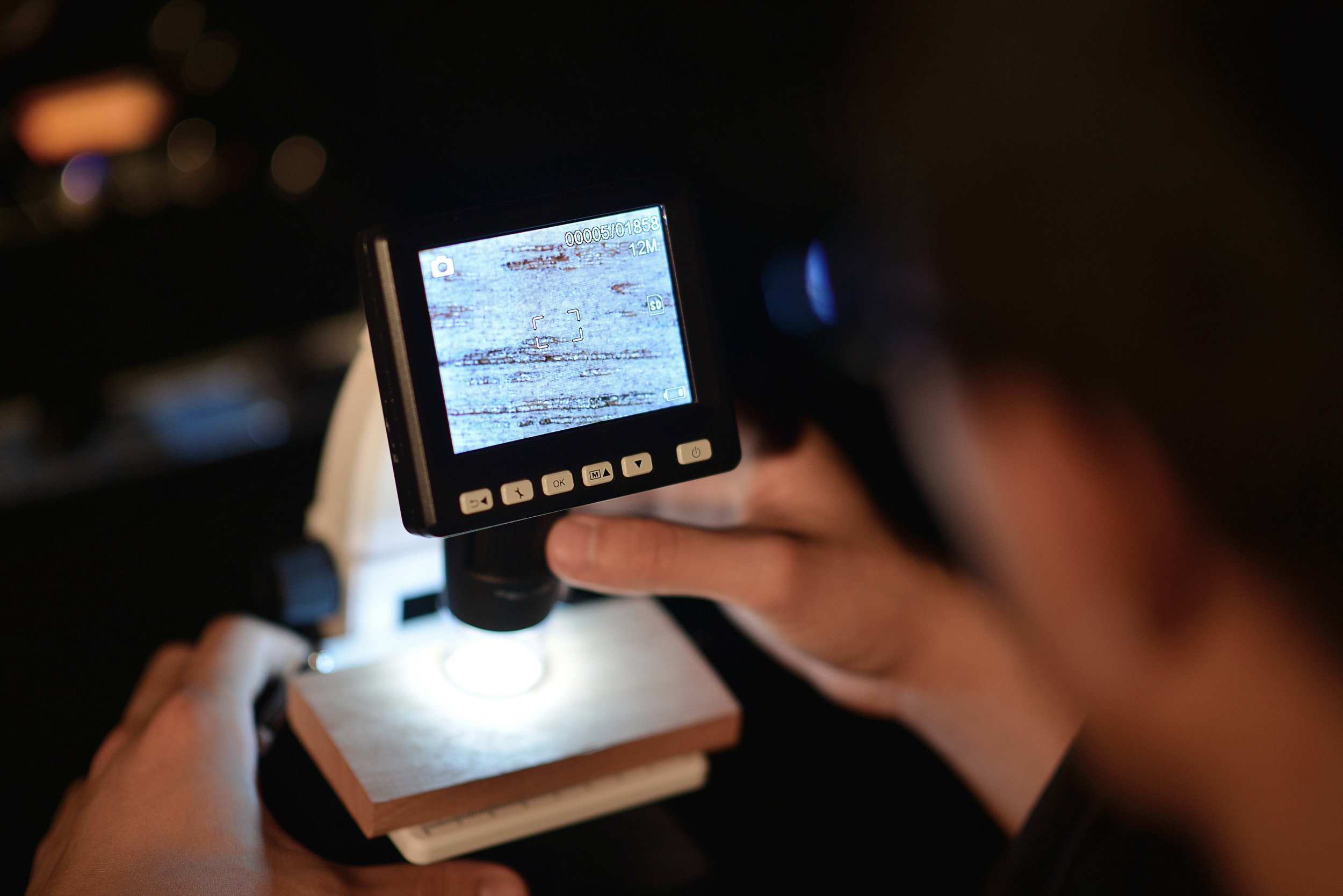

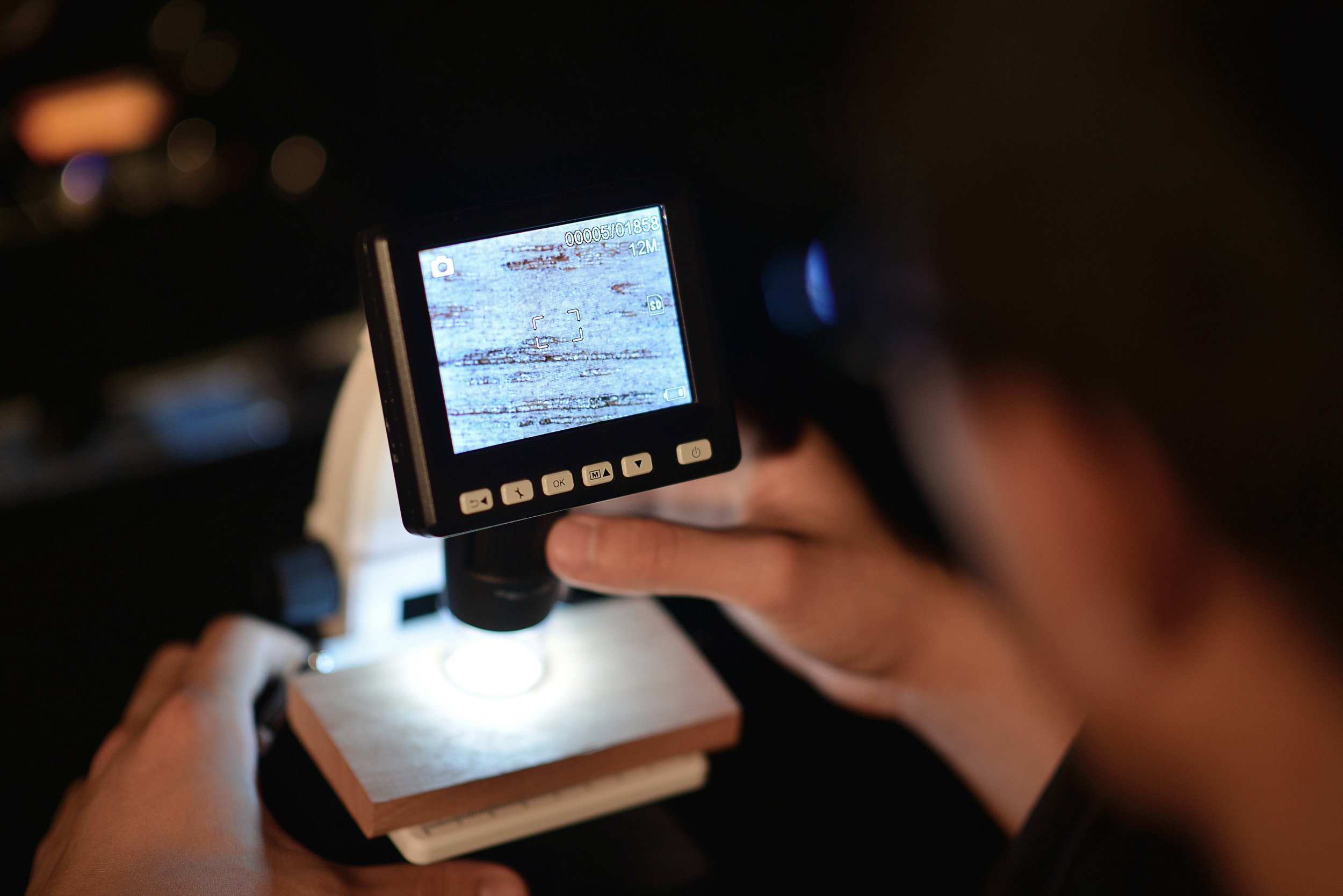

Wood Microscope

Studying the grain structure of various tonewoods gives us insight into how we can build better guitars — from the microscopic level up.

Under Scrutiny

An intense evaluation of every wood source helps keep Kepma Elite guitars perfect every time. Many times we’ll reject shipments of raw materials if they don’t meet our quality and integrity standards.

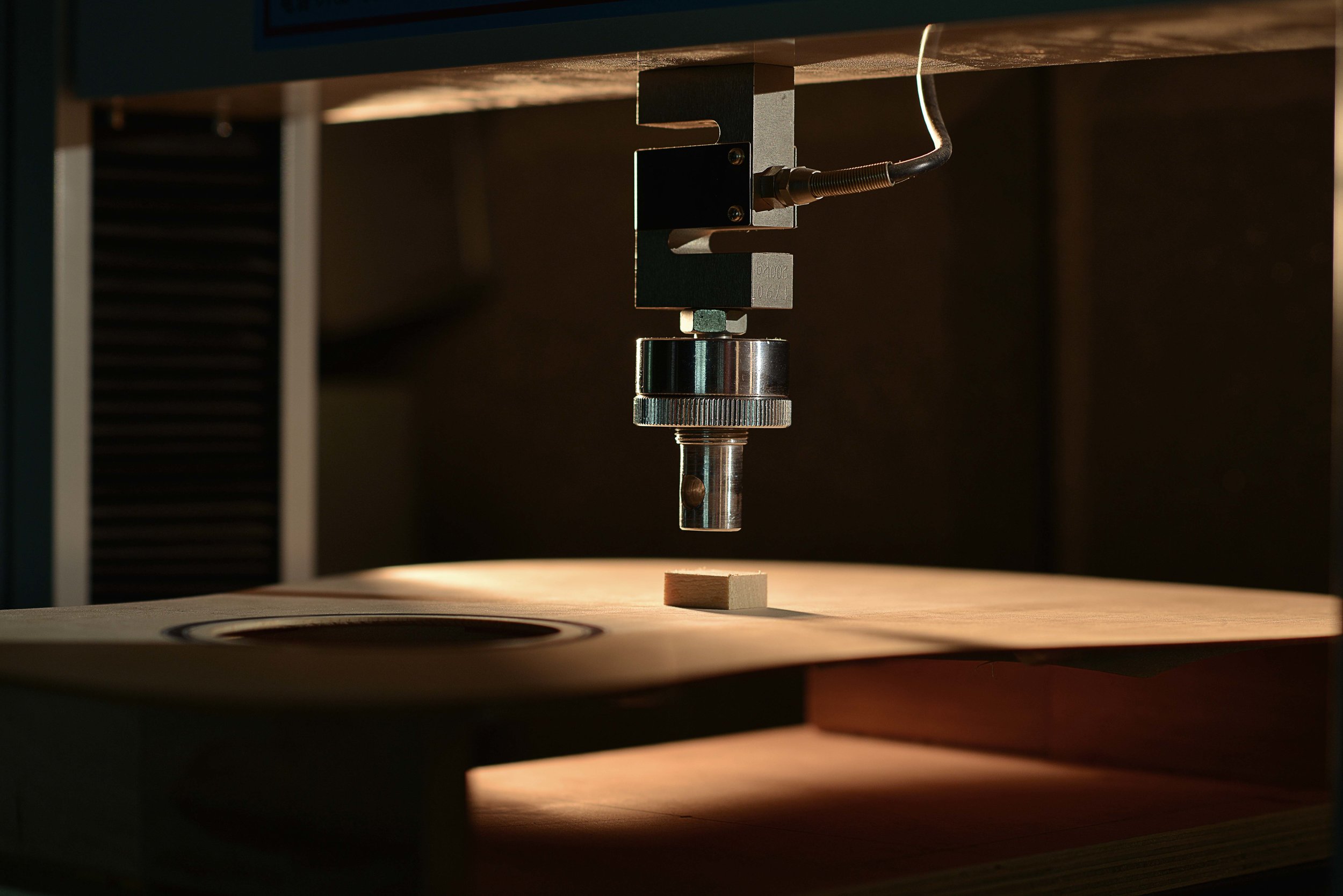

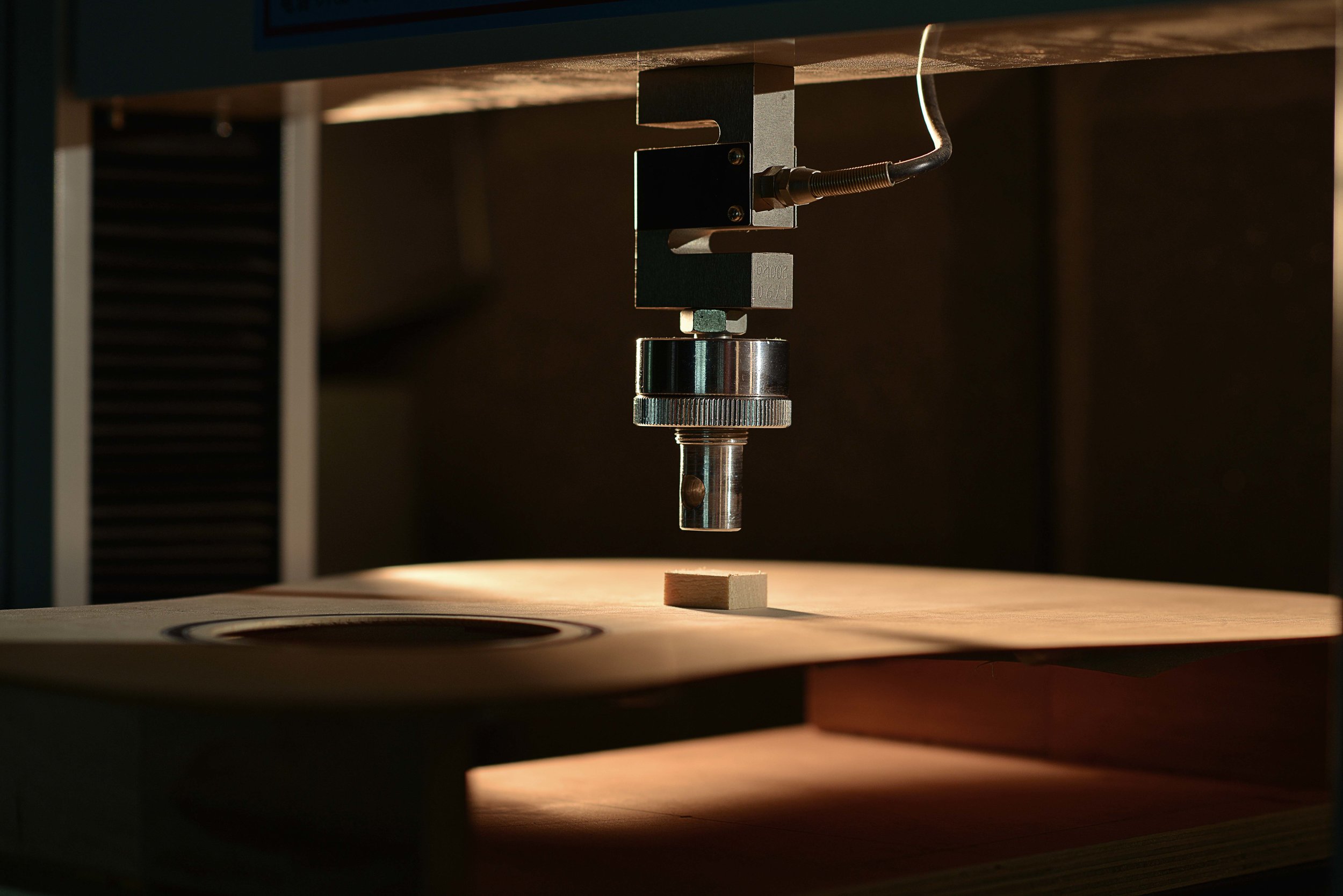

Pressure Testing

Pressure testing helps us determine the strength, resilience and even predict to a certain extent the tonal balance and response of our solid top guitars.

Strength Testing

Yes, we really do this. All of our raw materials go through an intense and rigorous testing process to ensure they’re up to our standards of excellence.

Bracing Prototype Development

We hand carve and test all of our bracing patterns to ensure they provide the strength where needed without impeding the tonal response of the top.

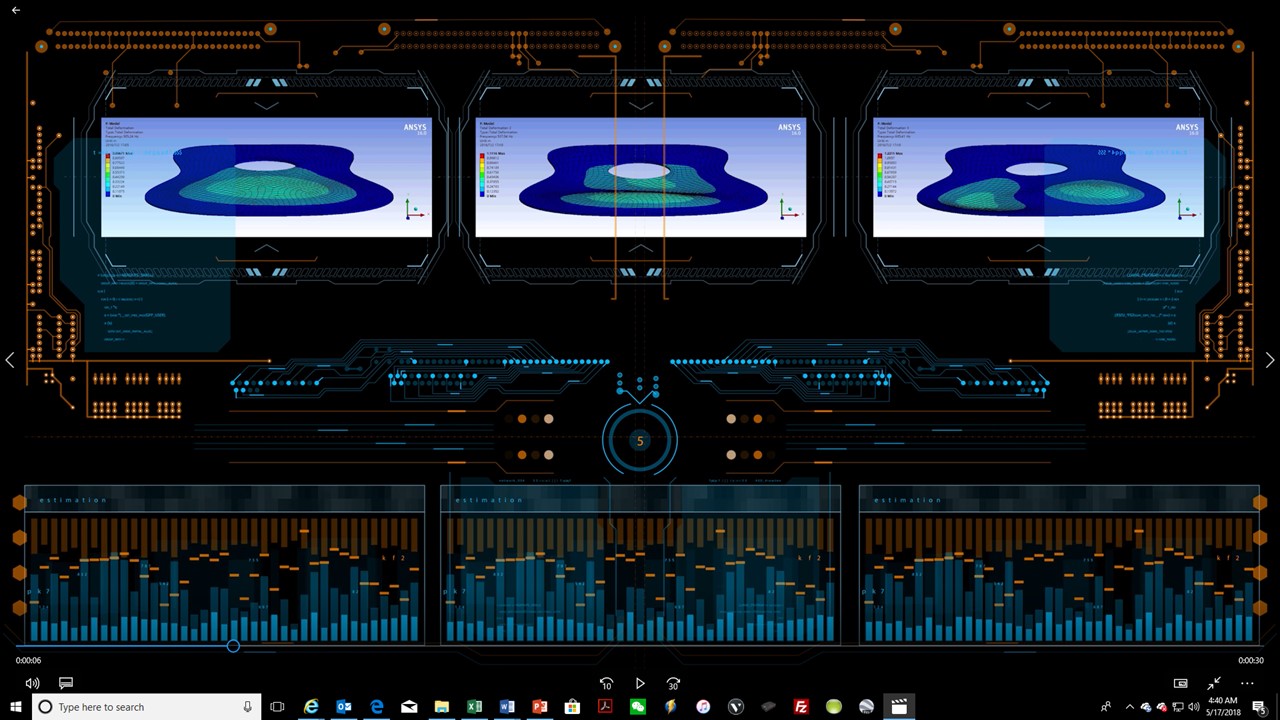

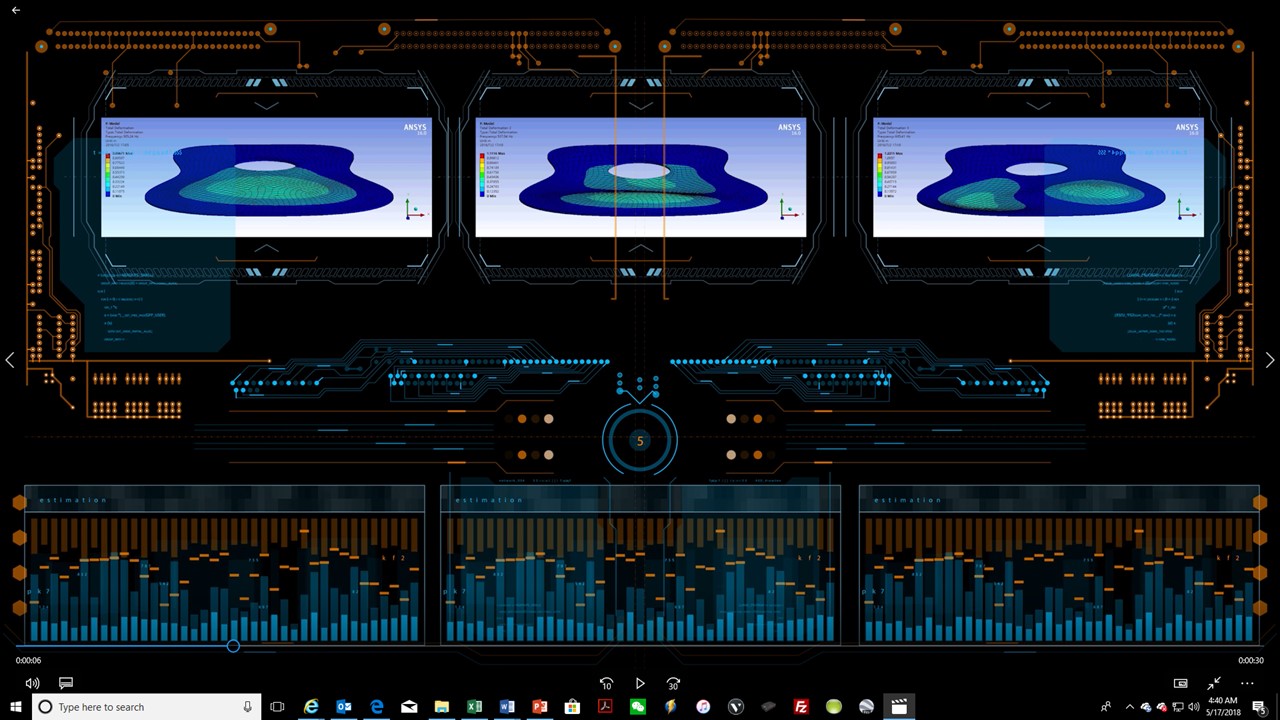

Modal Analysis

Every Kepma Elite solid top is thoroughly tested and evaluated for frequency response which ensures that every Kepma Elite Guitar will deliver a sound and performance that will exceed your expectations and quite frankly just put a smile on your face while you’re playing.

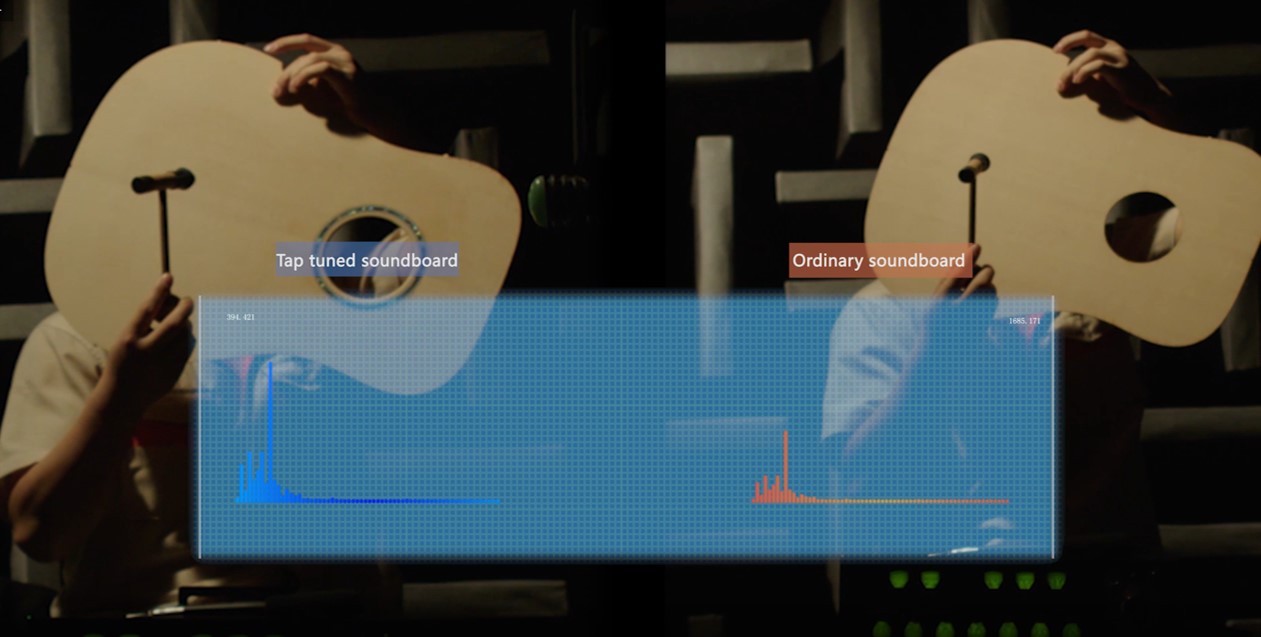

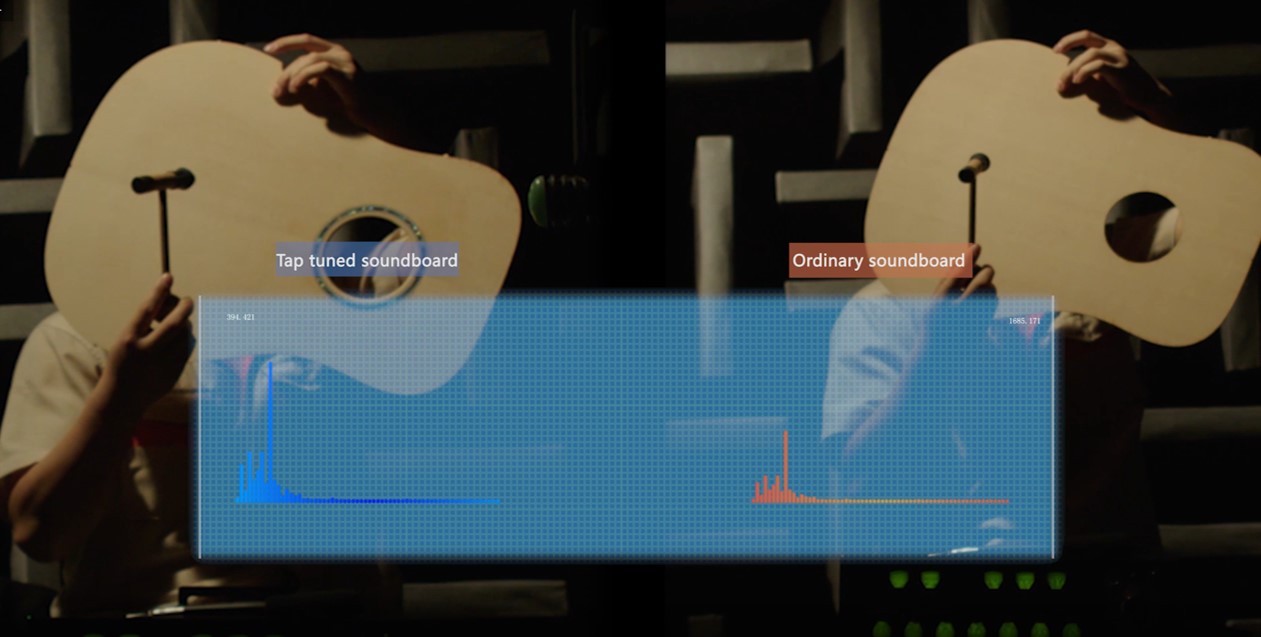

Spectral Analysis

What a perfect sounding top looks like to a guitar nerd…

Hand Tap Tuning

We don’t just use computers either. The golden ears of our R&D specialists can predict what areas of a top need to be adjusted before heading to the fitting rooms…

Water is bad for you...

Actually, not true. Every piece of wood has moisture content which helps it resonate and perform at optimum levels. We moisture-test all of our tonewoods to ensure that they’re “ready for primetime.”

Electronics Testing

In our R&D labs, we audio test every electronic component to ensure you’re getting the best acoustic sound from the pickup systems we install…

Hit the Air Showers

Before entering into the R&D labs, every foreign dust particle is removed from our bodies ensuring that nothing gets into a Kepma that isn’t supposed to be there.

Mother and Children

A giant Alaskan Sitka Spruce plug sits next to bodies headed off to the finishing booths…

White Lab Coats for Guitar Nerds

Yes, we really do wear them in the R&D department… it makes us feel like “tone doctors”… doh!

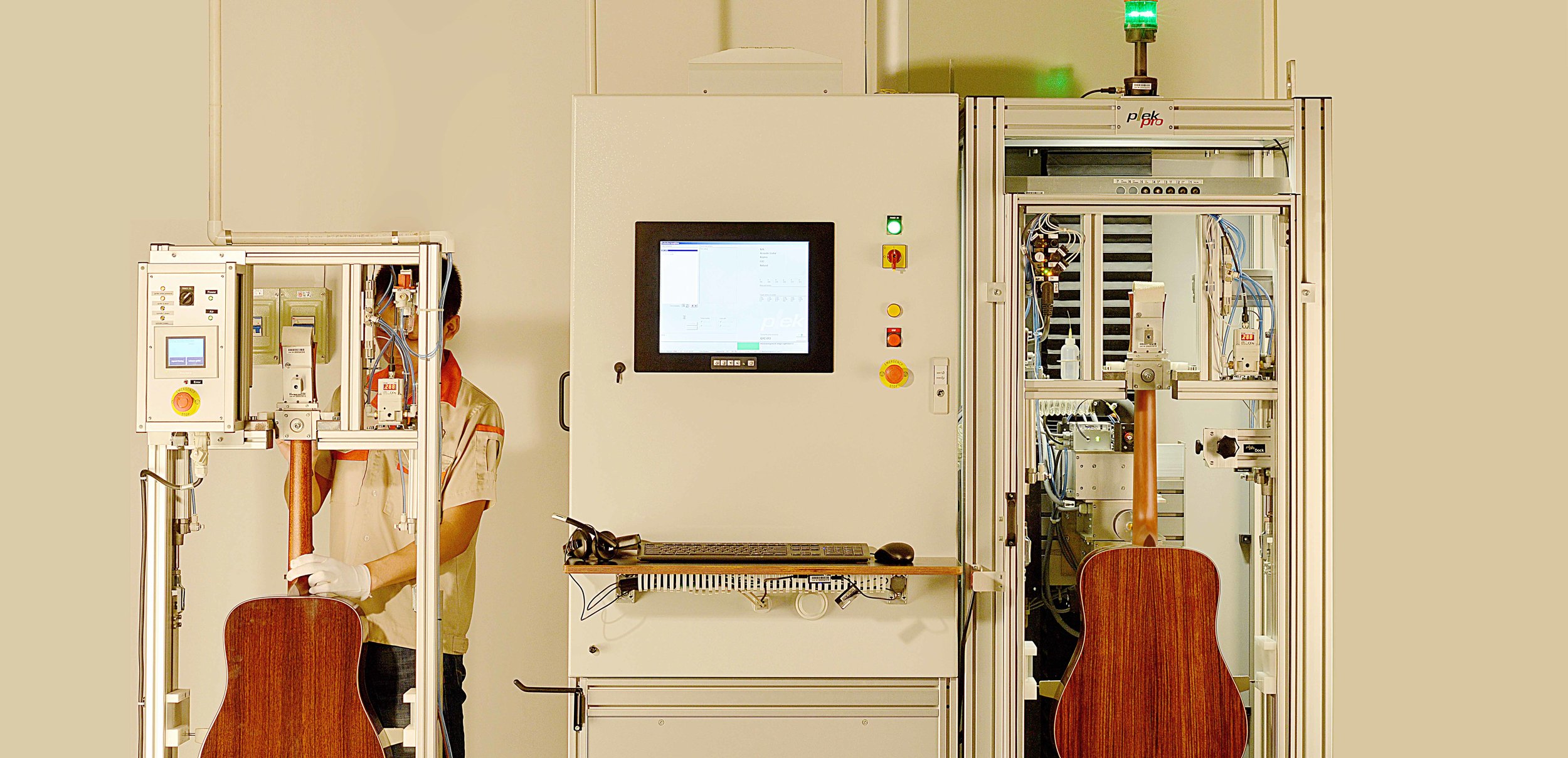

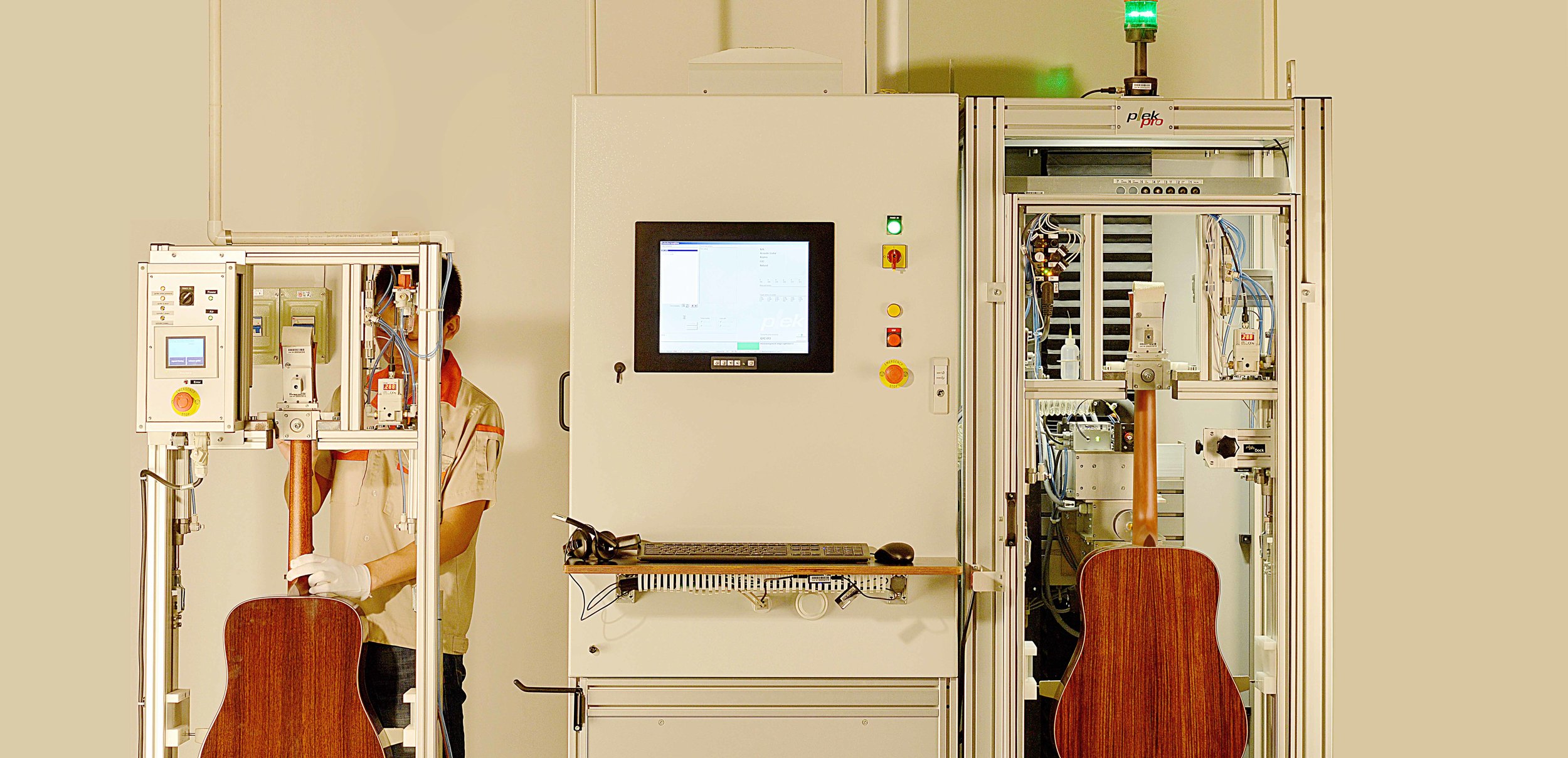

That's one Mother Plekker!

We have 3 Plek® machines that we use both on the R&D side for analysis and development of the perfect neck profile, and in the manufacturing process to ensure the perfect neck leaves our factory… well, perfect.

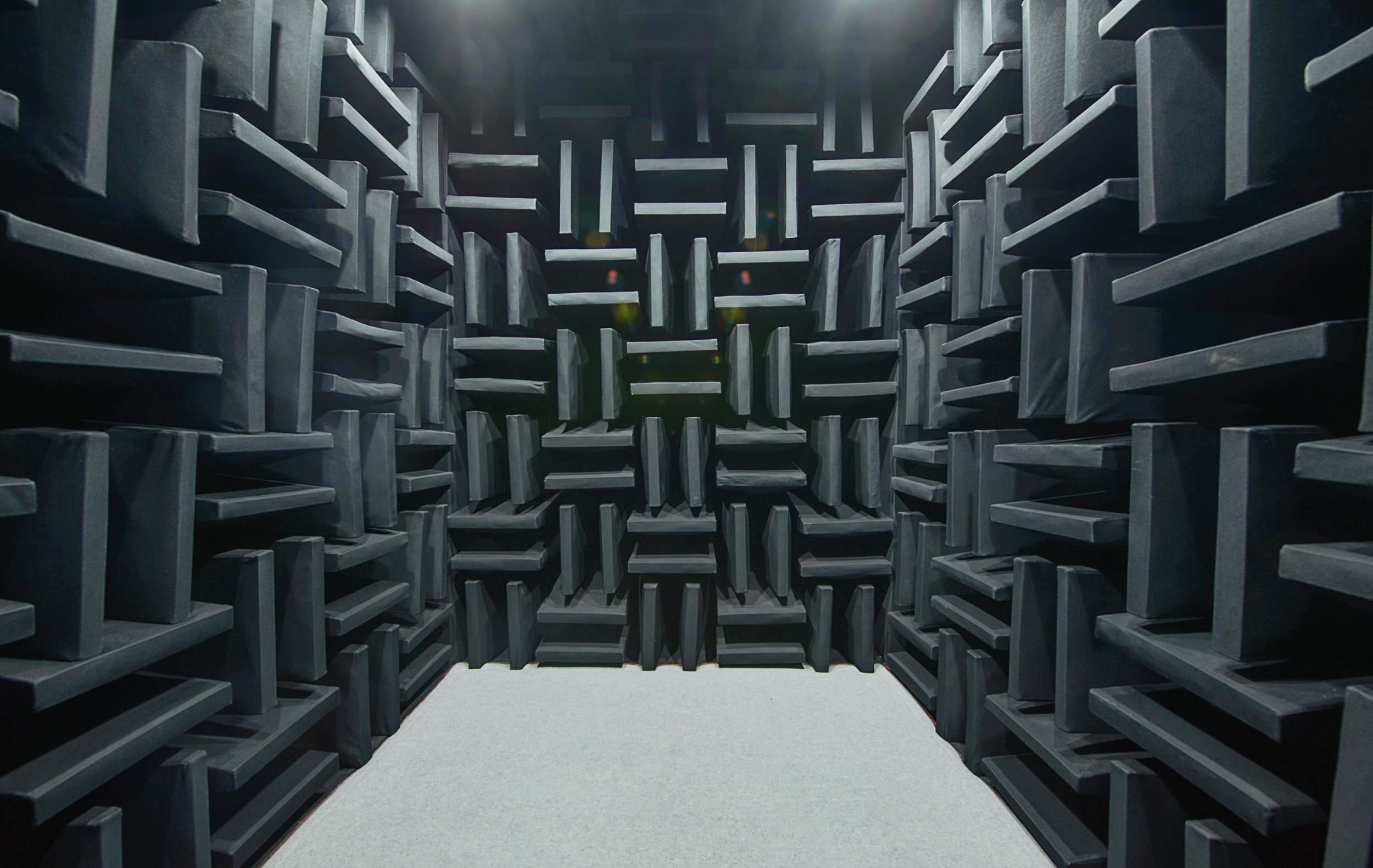

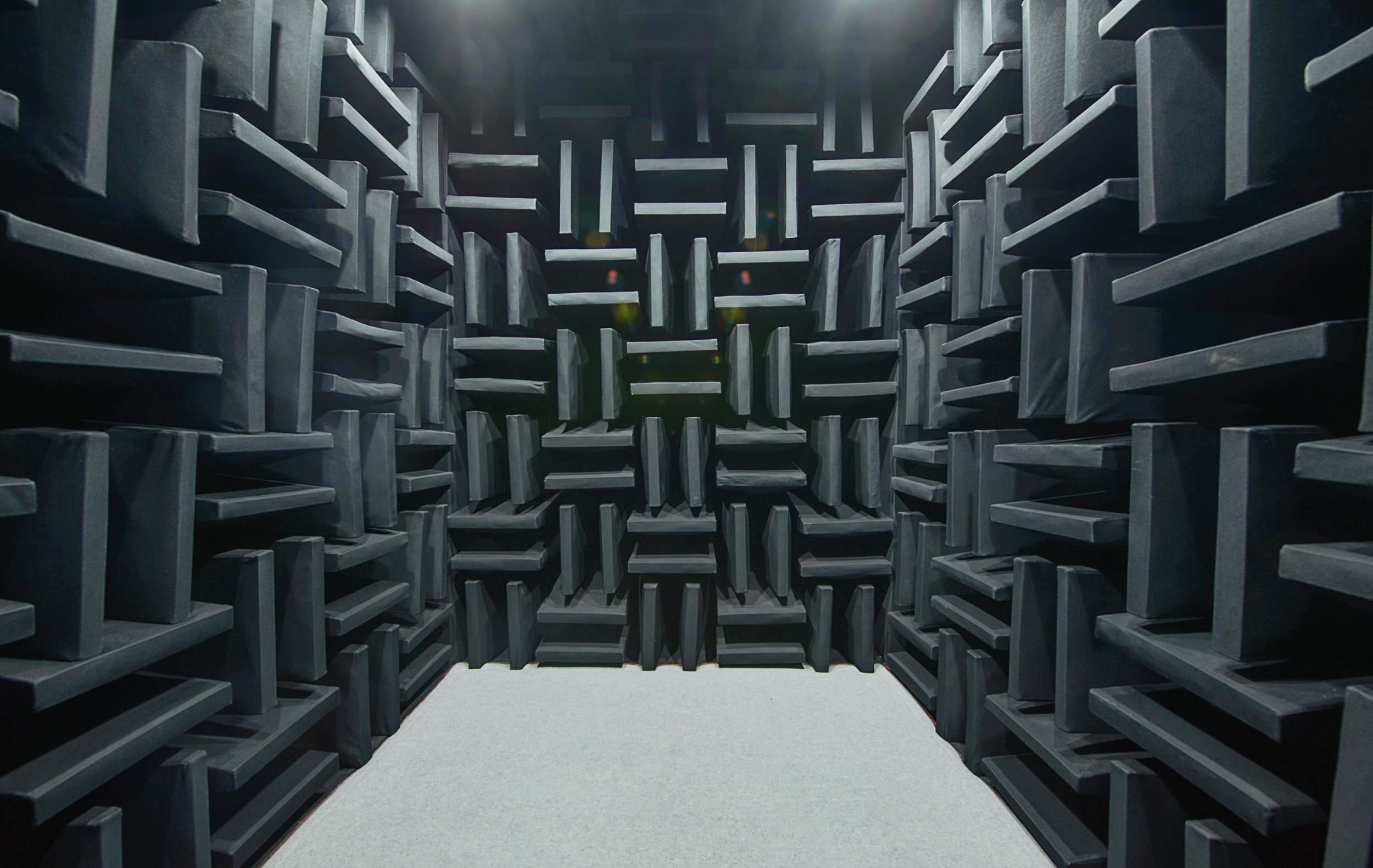

Hello, is this thing on?

Talk about a dead room! We also have one of the world’s largest anechoic chambers in our R&D facility for comprehensive testing and analyzing of the sonic character of the guitars we build.

Jack Peng, Co-Founder

You’ve heard about CEOs who aren’t involved in the day to day? Well, not here buddy. On any given day, you’ll find Jack in the R&D facility tinkering with designs, hand carving a new bracing pattern and genuinely inspiring our craftsmen to produce the best sounding instruments they can. It’s the Kepma way!